SH & AS series wire rope hoists

Electric wire rope hoists

The adaptable wire rope hoists from STAHL CraneSystems in a consistent modular system are designed for load bearing capacities from 500?kg to 160,000?kg.

26 bearing load versions

The versatile SH series is available in five design sizes with 26 bearing load versions for load bearing capacities from 500?kg to 25,000?kg. The upper bearing load range up to 100,000?kg is covered by the proven model AS?7. The SHW 8 winches expand the field of application to include heavy loads up to 160,000 kg.

- Compact, robust design

- Reliable,extremely powerful and very durable

- Especially soft, precise start-up and braking characteristics

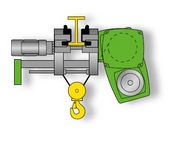

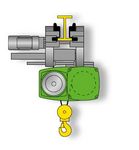

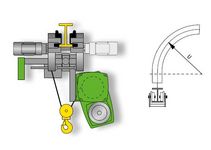

Wire rope hoist versions

Trolley versions of the wire rope hoists

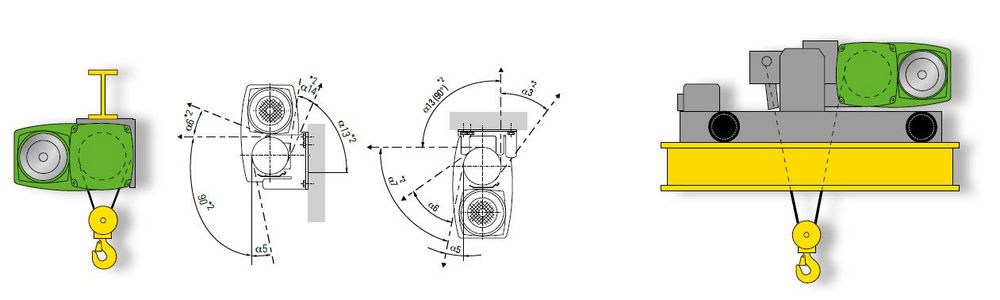

OE double rail crab

The OE double rail crab is designed for double girder overhead travelling cranes. Low approach and headroom dimensions are possible thanks to the very compact design, optimising the use of the available space. The double rail crab is available with various track gauges for the entire range of bearing loads and automatically compensates for any unevenness of the cross travel runway.

DKE articulated trolley

The DKE articulated trolley is available for frequently driving in curves and for tight radii. It is equipped with one or two travel motors depending on the curve radius, track flange width or use. The lateral guide rollers move with minimal wear. The DKE articulated trolley is designed for a load bearing capacity of up to 10,000 kg.

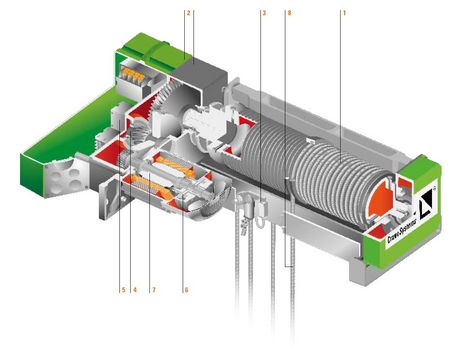

SH wire rope hoist: Technology

Knowing the sophisticated technology behind the SH wire rope hoist is reassuring. The largely maintenance-free components of the modular chain hoist are optimised to work together. They guarantee consistent performance, high efficiency and a long service life.

The standard safety components such as the gear limit switch, temperature monitoring of the motors and overload protection devices or an additional optional brake improve workplace safety.

8 Rope drive

- Optimised ratio of drum and roll diameter ensures low rope wear

- Flexible, durable wire rope

- Wear-resistant return sheaves, fine machining provides rope-friendly grooves in rope drum

- Freely accessible drum for rope replacement

- Robust hook block with small overall height notwithstanding large hook dimensioning

Options for wire rope hoists

There is always room for improvement. Numerous mechanical, electrical and electronic options are available to make your outstanding standard SH wire rope hoist even safer, more economical and convenient.

The service life of the wire rope hoist is also extended. Improve the performance of your wire rope hoist and adapt it to your individual needs with the options. Some examples of options are presented here.

SMC multi-controller

- Permanent load monitoring with overload cut-off, also when the lifting unit is standing still

- Overload protection through ALC automatic load control

- Load spectrum recorder for load-specific run time accumulation

- Monitoring of the lifting motor and travel motor temperature

- Production data acquisition, for example, hours of operation, load spectrum, motor circuits and load cycles

- Data can be exchanged with a PC

Frequency converter for "lifting"

- Smooth starting and braking characteristics

- Load swing greatly reduced

- Fast, precise positioning of the load, corrective switching operations rarely necessary

- The reduced dynamic load extends the service life of the lifting motor and gearing, and protects the entire system.

- ESR (Extended Speed Range) function for higher lift speeds under partial load

- Worldwide approvals of all frequency converters

- Certified according to DIN ISO 9001

Frequency converters for trolley/crane movements"

- Straightforward installation, parametrisation and operation

- Standard speed range 1:10, optionally up to 1:30

- PLC compatible with higher-level systems (optional)

- All common international mains voltages are covered.

- Also available in a control cabinet version

Explosion-protected version of the wire rope hoists

Optionally the wire rope hoists and corresponding

accessory components are also available in explosion-protected versions.

Wire rope hoist questions and consultation:

If you have questions, need special wire rope hoist solutions or

would like a telephone consultation, please call us.

Our experts are looking forward to your call:

Robert Seibold

+49 8543 / 9618-17

robert.seibold@metallbau-haslinger.de

Thomas M?rzendorfer

+49 8543 / 9618-30

thomas.maerzendorfer@metallbau-haslinger.de