Piece-work cuts for every area

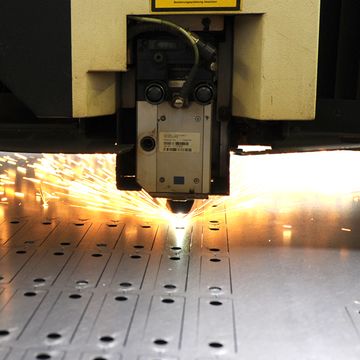

2D - laser cutting

Individual solutions for fine and thick sheet processing,

creation of prototypes, individual parts and

small and large series.

The most modern laser technology

- Tru Laser 3030 (L20)

- Contours up to a max. panel size of 3000 x 1500 mm and panel thickness up to 25 mm (construction steel), up to 20 mm (stainless steels) and up to 12 mm (Aluminium)

Advantages

- almost unlimited variety of shapes

- minimal heat generation in the sheet part

- outstanding and absolutely consistent quality

- no mechanical processing, protects the work-piece

- fast and cost-effective processing possible

(in contrast to milling, sawing, drilling) - Manufacture of both prototypes and individual pieces and small and large series no tool costs

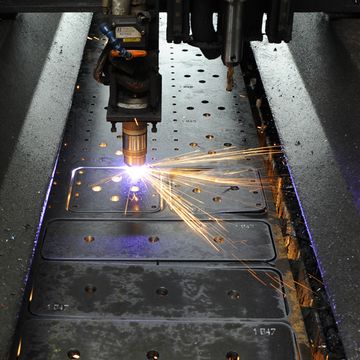

Ficep Gemini 32 for sheet processing

(Steel, stainless steel)

- Format: max. 3000 - 8000 mm

- Material thickness up to 80 mm (Steel)

- Material thickness up to 30 mm (for stainless steel)

- 3 flame cutter heads

- 1 Plasma cutter

- Drill unit from 6.8 - 32 mm

- Countersinking + thread-cutting possible

- With 8-tool changer

3D-Plasma system

with tube cutting equipment

5- axle plasma system with tube cutting equipment and automatic angle cutting head for cutting sheets, tubes and profiles. Work can be carried out quickly and

flexibly with the machine even without programming.

Flexible technology= flexible calculation

- Power: 10.5 kW

- cutting range: 3,100 x 2,100 mm

- Cutting thickness for sheet:

- Construction steels (S235, S355): up to 100 mm

- Stainless steels (1.4301, 1.4571): up to 100 mm - bevel cutting:

- angle range from 0-45° - Tube cutting equipment:

- tube diameter 50 – 300mm

- Max. tube length: 3,000mm